Frying oil offers enormous cost savings

Frying oil is one of the biggest cost factors in professional kitchens. Frequent oil changes lead to higher costs, poor oil management affects the taste of food and customer satisfaction, and the disposal of used oil creates additional waste and environmental impact.

Frying oil offers enormous cost savings

Consistent oil quality increases customer satisfaction

Sustainability and responsible use of resources

Daily manual filtering is no longer necessary

The OLFO frying technology was developed as part of a Swiss government-funded research project (CTI) worth 1 million CHF, in collaboration with ETH Zurich and ZHAW. Extensive testing showed that OLFO’s membrane filtration system can extend the life of oil up to three times while maintaining oil quality at an industry-leading level.

All data is based on research conducted by ETH Zurich and ZHAW. For detailed reports, contact us at sales@gastrofrit.ch.”

Unlike traditional fryers, OLFO continuously regenerates frying oil using innovative nano-membrane filtration. This removes impurities in real time — no chemicals, no additives — ensuring consistent frying quality and healthier food

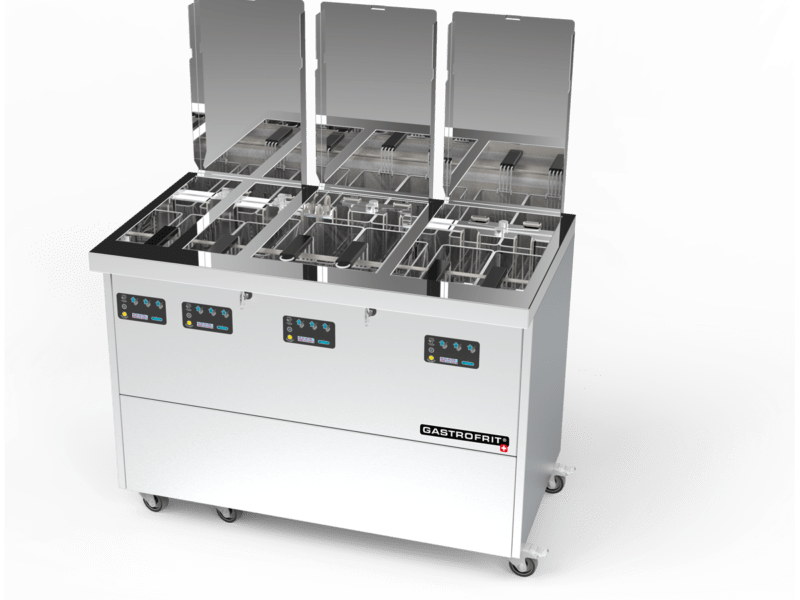

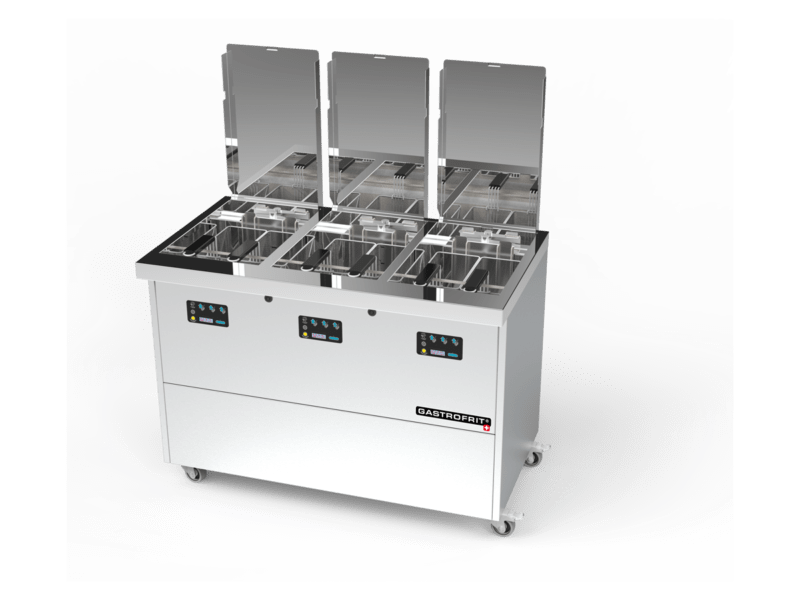

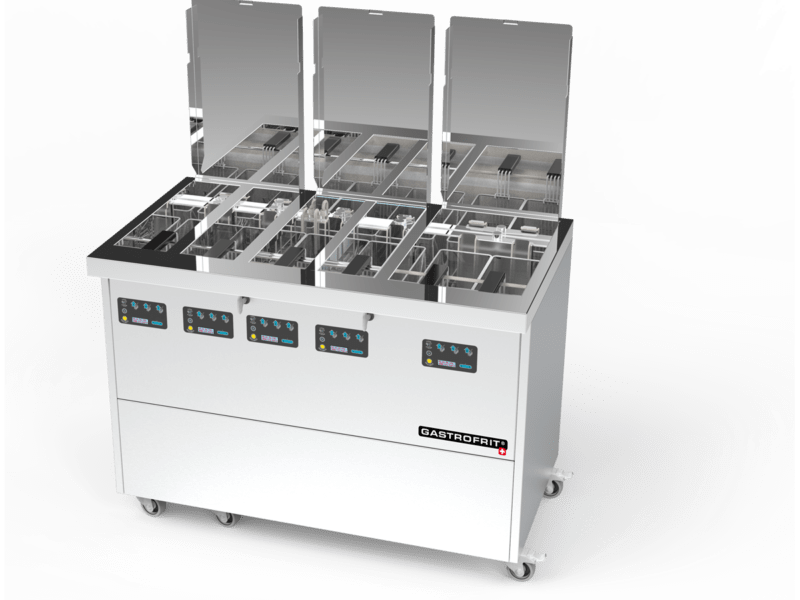

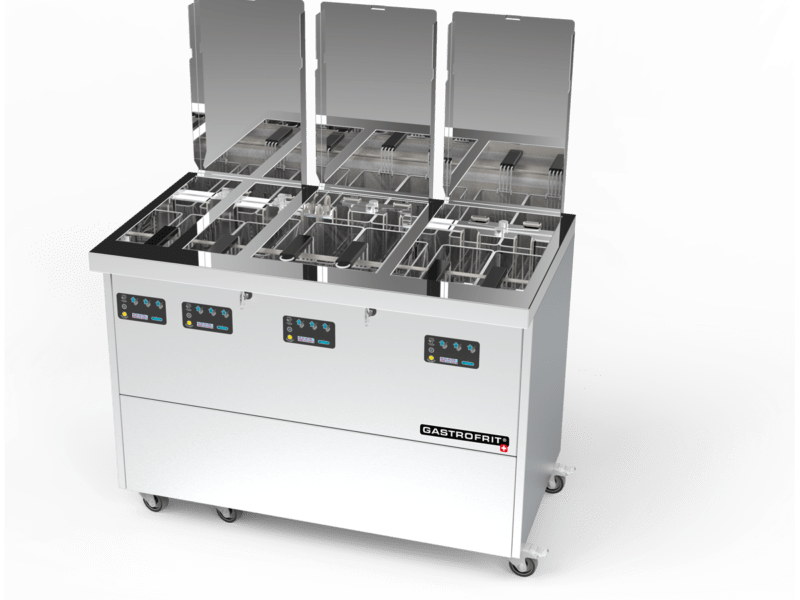

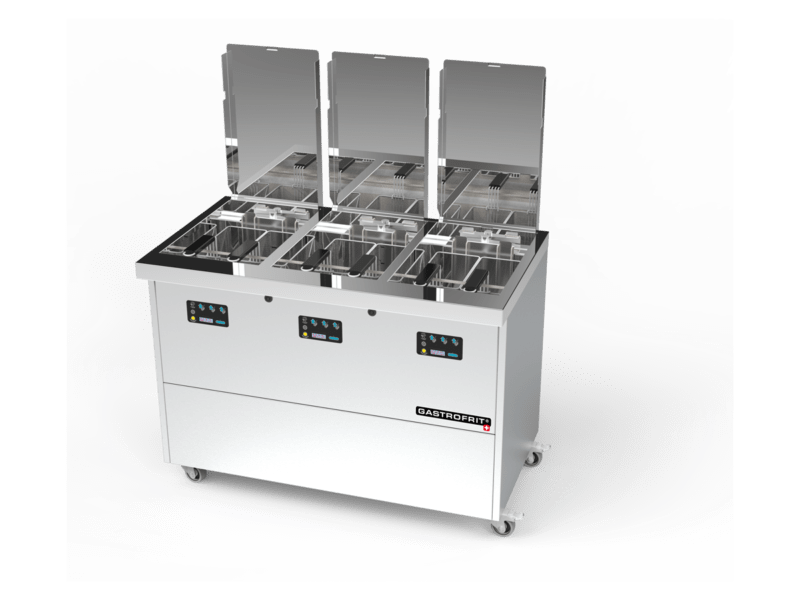

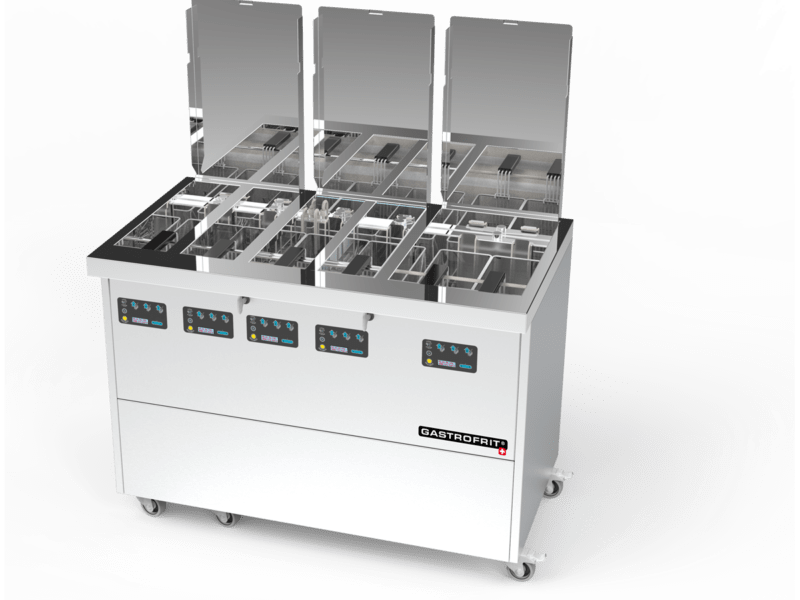

Discover the four OLFO fryer models and quickly find out which one best suits your kitchen’s needs.

Each variant comes with a brief description as well as visual details on oil volume, power, and hourly output — allowing you to easily compare performance and efficiency and choose the right solution

Use our product comparison tool to explore all the technical specifications of the OLFO variants A, B, C, and D in detail.

Wer profitiert am meisten von OLFO?

OLFO is more than a fryer – it is an intelligent oil management and filtration system that makes professional kitchens more efficient, economical, and sustainable.

Restaurants, caterers, large-scale kitchens, and QSR franchises benefit from consistently high product quality, reduced oil consumption, and significantly less maintenance effort.

OLFO adapts seamlessly to the needs of modern gastronomy and foodservice operations.

Restaurants across Europe consume around 1.3 million tons of frying oil annually, with up to 60% ending up as waste. Thanks to OLFO’s continuous oil regeneration, this waste is reduced to just 2% — representing a potential saving of 760,000 tons of oil per year

Lower environmental footprint

Less oil waste, lower disposal costs

Healthier food with fewer harmful compounds

Oil circulates through a nano-membrane that separates pollutants and impurities at the molecular level. This keeps oil cleaner, safer and usable for much longer.

Most kitchens see up to 65% oil savings and 15–20% energy savings. Combined with lower cleaning costs, ROI is typically reached within 2–3 years.

Not at all. The fryer features a one-touch filtration system and needs minimal manual cleaning. No more handling hot oil for filtering!