Explore Gastrofrit® Solutions

Deep Fryer

Bring the art of fresh pasta into your kitchen with Gastrofrit’s Swiss-made machines. Our systems are modular, easy to use, and built for restaurants, hotels, and catering businesses. Increase menu variety while reducing preparation time and labor costs.

VISIT SHOP

Pasta Devices

Maintain peak performance with original Gastrofrit accessories and certified spare parts. From replacement filters to custom add-ons, we ensure your equipment runs smoothly and efficiently. Fast delivery and guaranteed compatibility keep your kitchen always ready.

VISIT SHOP

Accessories and Spare Parts

Discover the revolutionary OLFO Fryer that cuts oil consumption by up to 65%. Built with advanced membrane filtration and intelligent heating, it delivers consistent food quality, lower operating costs, and easier maintenance. The smart choice for high-demand kitchens.

VISIT SHOPIndependent Research Confirms: Better Oil Quality, Longer Life

Our OLFO Fryer technology has been validated by leading Swiss universities ZHAW and ETH Zurich in a CTI-funded research project (OLFO 19293.1). The results speak for themselves:

- Oil degradation reduced by more than 50% — from 27% down to just 11.8%

- Consistent taste quality for months instead of weeks

- Stable performance under real kitchen conditions proven in long-term trials

- Reduced acrylamide formation, thanks to better control of frying temperature and oil stability

- Scientifically documented ROI, showing direct cost savings and higher food quality

The Core Benefits of OLFO Technology

From oil savings to superior taste, discover the five key advantages that make OLFO Fryers smarter, cleaner, and more profitable for your kitchen.

- Oil Savings – extend oil life up to 3× and save over 50% on replacements.

- Food Quality – Consistent taste, crispier results, and reduced acrylamide formation.

- Labor Light – Save staff hours with one-touch cleaning and fewer oil changes.

- Energy Smart – Three-section heating and standby mode cut waste and preserve oil.

- Eco-Friendly – Less waste oil to dispose of — smaller footprint, greener kitchen.

- 1 Continuous membrane filtration removes particles down to 40 μm.

- 2 Intelligent three-section heating keeps oil stable and energy costs low.

- 3 One-touch cleaning system simplifies daily operations.

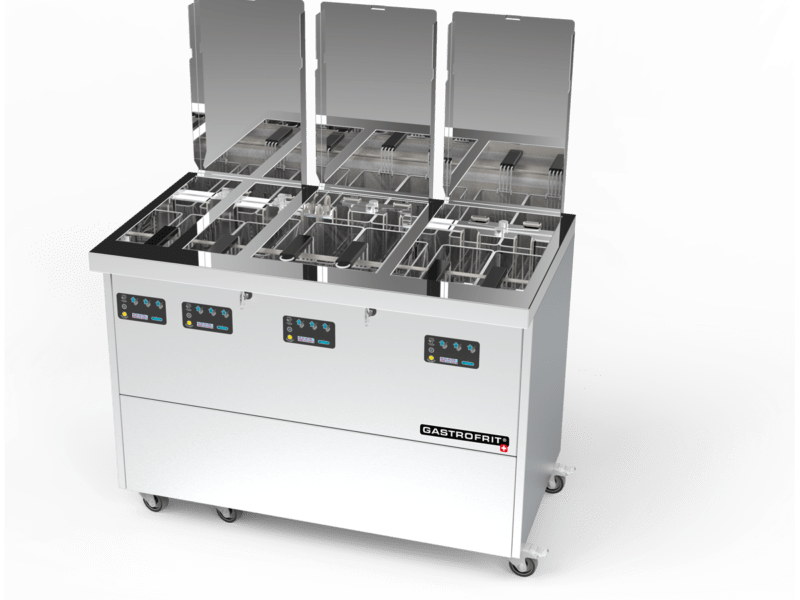

DEEP FRYER electromechanical control

The device is designed for a long lasting everyday use. It has been integrated a resistant electromechanical control. The series is suitable for Gastro-kitchens, snack and catering establishments.

Customization

- Automatic oil filtration system

- Base unit (height) 900mm

Effortless Cleaning

- Boil dry protected telescopic heating element: any remains rub off

- Logical design: rounded off, no superfluous edges

- Appliance on four rollers

- Oil filter sieve

- Optional: oil filtering system

Energy Efficiency

- Automatic energy-save mode and stand-by function

- Large heating surface helps the oil heat up gently

Swiss Precision

- Top quality, stainless steel

- Precision finish

- Maintenance friendly

- Safety thermostat

- IPX 5 approved (splash-proof)

- CE and TüV tested

- Available bulit in solution

Compare OLFO vs. Traditional Fryers

See how OLFO outperforms other fryers on the market in every key area — oil consumption, energy use, cleaning effort, and ROI.

Feature

- Oil Consumption

- Filtration System

- Cleaning Process

- Energy Efficiency

- Food Quality

- ROI

OLFO Fryer

- Up to 65% lower

- Integrated & automatic

- One-touch filtration

- Smart heating, lower costs

- Consistent taste & texture

- 2–3 years

Traditional Fryers

- High usage

- Manual or none

- Labor-intensive, daily

- Higher consumption

- Fluctuations, off-flavors

- Slower payback

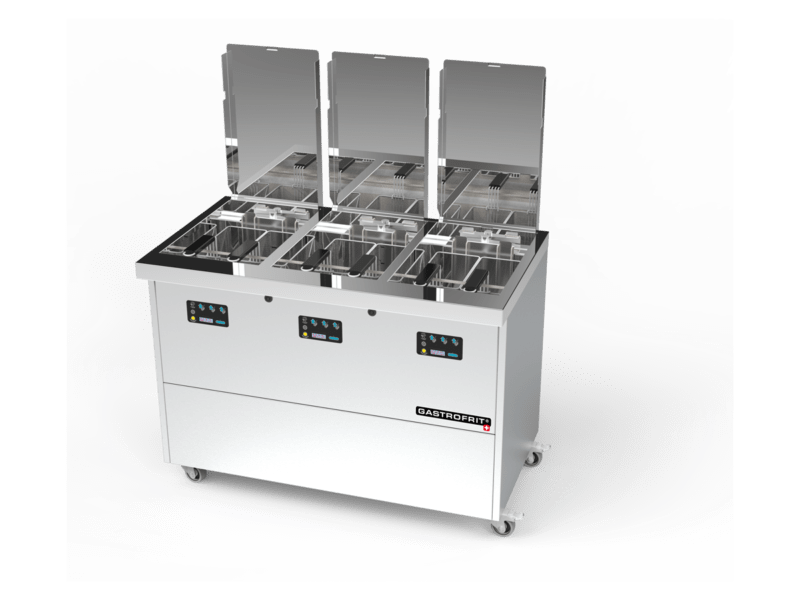

DEEP FRYER electronic control

Our new deep fryer is a built up system in modules. As standard it has an integrated telescopic heating system. For more comfort it can be replaced with the option removable plug –in heating element. Your device can be calculated with an automatic basket lift system and automatic oil filtration. Please note that all expansion variants are also available as built-in variants.

Benefits

- Simple operation from a key pad

- Economical due to optimal heating control

- Logical construction: rounded

- Large heating surface for gentle heating

- Standby function (temperature and time can be selected)

- appliance on four rollers floor conserving the material

- CE approved

- Available as a thought out built-in solution

Oil-friendly

- Oil-friendly heating system

- Melting fat cycle integrated

Unique selling position

- Automatic safety drain by pushing a button

- Heating can be unplugged

- Calculated time based on the amount of oil

- Automatic oil filtration

- Power Heating

- Substructure 900 mm

- Energy optimization

- Two different pools can be combined

Adjustable volume

- Integrated acoustic timer

- Adjustable volume

- Watch Volume System

Choose Your Electronic Fryer

-

F-300 electronic device

5'084.00 CHF -

F-400 electronic device

6'607.00 CHF -

F2-400 electronic device

8'217.00 CHF

Discover the OLFO Advantage

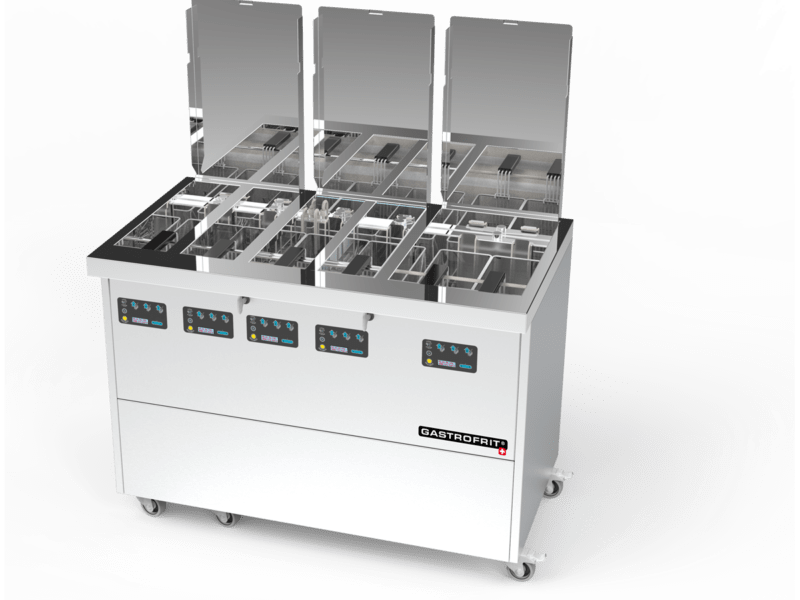

DEEP FRYER CENTER

The Olfo fryer covers all of your frying requirements. The Olfo is designed for use in the system catering industry. Its ease of use and stable construction are ideal to cope with rough handling by its users. Baskets and vulnerable surfaces have been braced and reinforced. With an audible alert system and automatic basket lifting, everyday deep-frying is a simple task.

Control box

- All parts follow the plug-in principle

- Two-line display in real time, for the complete display of instructions and error information

- Standby function

- The latest SSR (solid-state relay) pulse switch

- In conjunction with temperature measurement using the PT-1000, control and monitoring are unsurpassed.

- The display can be operated up to 3 meters away from the fitting box.

- No programming and no expertise are required.

- Ultra-simple operation using the membrane keyboard.

Automatic oil filtration

- Oil filtering system offers the possibility of cleaning the frying oil at the touch of a button

- The filtering process is controlled and monitored electronically

- The oil is continuously filtered and regenerated

- No longer replace the oil but instead only top it up

General benefits

- Intelligent heating technology

- Watchvolume

- Power heater

- Oil-check system (sensor)

Plug-in heater

- The energy is emitted almost entirely directly.

- The interior of the fryer is easily accessible and easy to clean.

- The heater goes in the dishwasher

- Service-friendly

- The changeover to a power heater is possible at any time.

Choose Your Fryer Center

-

OLFO Variant A

35'712.00 CHF -

OLFO Variant B

33'606.00 CHF -

OLFO Variant C

37'808.00 CHF

Fresh Pasta: Authentic Taste, Swiss Precision

Bring the art of fresh pasta into your kitchen. Gastrofrit’s modular pasta systems are designed for restaurants, hotels, catering, and multi-unit chains. With Swiss-made quality, they combine flexibility, ease of use, and reliable performance — ensuring authentic results with lower labor effort.

- Target Groups: Quick service, multi-unit chains, catering, hospitality

- Customization: Adapted to your menu and workflow

- Performance: Faster ROI compared to traditional pasta solutions

- 1 Mix & Extrude Fresh dough is automatically mixed and extruded into your desired pasta shapes — consistent quality every time.

- 2 Cook & Drain Integrated cooking systems ensure perfect al dente pasta, with optimized water usage and automatic draining.

- 3 Serve & Enjoy Deliver authentic fresh pasta in minutes, ready to be plated for your guests with minimal labor.

Customization & Flexibility

PASTA DEVICES

With the new device,you have the possibility to produce a varietie of fresh pasta. For your new project, you can even create your own pasta After a short training period you can start your pasta production by your own. You create pasta in various colors and flavors Several tools which ensure a constant quality are available. You can also define your own matrix, inventing own pasta creations. Give free rein to your ideas and set yourself apart from your competitors

Customization

- 2 x programmable automatic basket-lift mechanism

- Electronic sensor for optimal dosing of salt

- Base unit (height) 900mm

- Electronically controlled refilling

- Electronically controlled safety relief valve

Effortless Cleaning

- Boil dry protected telescopic heating element: any remains rub off

- Logical design: rounded off, no superfluous edges

- Appliance on four rollers

Energy Efficiency

- Simple key pad operation

- Less work than with a conventional hotplate

- Automatic temperature control

- Top performing heat source for high-performance

- Mise en place preparation

- Consistent quality even with different kinds of pasta

- Suitable for cooking rice and vegetables

- Different sized portion holders made of special chrome steel

- Automatic energy-save mode and stand-by function

- Eletronic continuous starchscouring

Swiss Precision

- Top quality, special chrome steel

- Precision finish

- Maintenance friendly

- Safety thermostat

- IPX 5 approved (splash-proof)

- CE tested

- Also available bulit in solution

Choose Your Pasta Device

-

PMM-151 productionmachine for pasta

13'723.00 CHF -

PMM-181 productionmachine for pasta

16'744.00 CHF -

TW-400 Pastacooker (electronic device)

7'392.00 CHF

Compare Fresh Pasta Technology vs. Traditional Methods

See how Gastrofrit’s pasta devices outperform manual preparation in every key area — efficiency, consistency, labor savings, and scalability.

Feature

- Consistency

- Labor Effort

- Speed & Scalability

- Flexibility

- Quality Control

- ROI

Fresh Pasta Technology

- Uniform texture and authentic al dente taste

- Semi- or fully-automatic operation, minimal manual work

- High-volume production, multiple pasta formats

- Wide range of pasta types with one system

- Precise dosing, cooking & finishing options

- 2–3 years through labor and waste reduction

Traditional Pasta Making

- Irregular results depending on staff skills

- Labor-intensive, time-consuming

- Limited output, small batches

- Few formats, restricted by manual shaping

- Hard to standardize, frequent fluctuations

- Slower return due to higher costs

WE WORK WITH THE BEST PARTENRS

Our technologies are branch leading and support our customer in reliably archieving their goals in the daily gastronomy business.

OLFO® The new membrane technology. No need to dispose of frying oil after three days.

The professional planer contains all necessary documents for plan the kitchen side.

Sustainable values needs sustainable organization. Your vision - our pasta devices.